by admin | Jul 26, 2022 | Uncategorized

Clayton Equipment Ltd based in Burton-on-Trent, UK has sold and delivered five (with an option for a sixth) CB12.5 state of the art lithium-ion battery locos for Glencore’s Onaping Depth nickel-copper mine in Sudbury, which are notable as being the first Li-ion...

by admin | May 12, 2021 | Uncategorized

Mining companies are digging deeper than ever to maximize output, what starts as an open-pit mine often extends underground. “As mines get deeper, extraction of valuable ore becomes more costly,” said Derek Meloche, manager of business development, Variant Mining...

by admin | Nov 3, 2020 | Uncategorized

In the last few days of Steve Matusch’s life, he had a conversation with his friend Andre Dumais about the importance of keeping the Sudbury Rocks! race going. Matusch was the founder of the annual Sudbury Rocks race and died earlier this year after getting a...

by admin | Oct 12, 2020 | Uncategorized

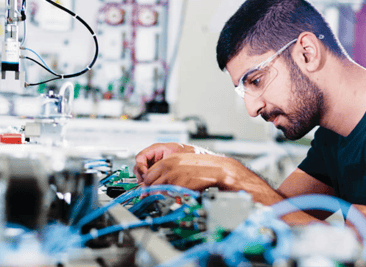

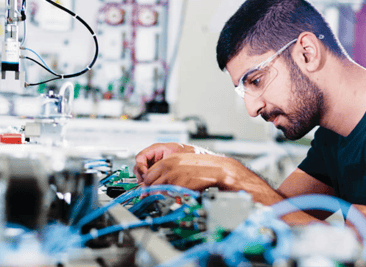

Automation is often discussed in alarmist terms—at least, when it comes to employment. A headline-grabbing 2018 RBC report found that at least half of Canadian jobs will be impacted, if not altogether eliminated, by automation. But the report also suggested that...

by admin | Oct 5, 2020 | Uncategorized

Participate or support through donating to either Andre Dumais or Greg Williams… every bit helps, no matter the amount.