WELCOME TO VARIANT MINING TECHNOLOGIES

Variant Mining Technologies is a leader in providing clients with muck circuit material handling solutions, solving some of the industry’s biggest challenges in moving material safely and efficiently, while remaining cost competitive. As an innovation driven company with roots in an internationally recognized mining center, our growth plan has always been focused on staying ahead of the curve by introducing new technologies to the industry. We put our clients first, evaluating your challenges with specific focus on introducing the latest technologies into our solutions. Our technologies have proven to increase the safety of your operations, gains in productivity, extended life of your equipment and reducing operational costs. Our products range from Loading Chutes to Underground Rail Haulage to wireless control packages – we stand behind every product we sell.

Send Us A Text

Email Us

705.692.1520

If you’re too busy to chat now, please enter your cell # and message below and we will text you back as soon as possible.

OUR PRODUCTS

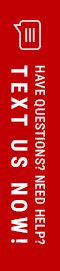

Loading Chutes

Variant Mining Technologies (VMT) loading chute systems have proven to be the equipment of choice to many Tier 1 Mining Clients…

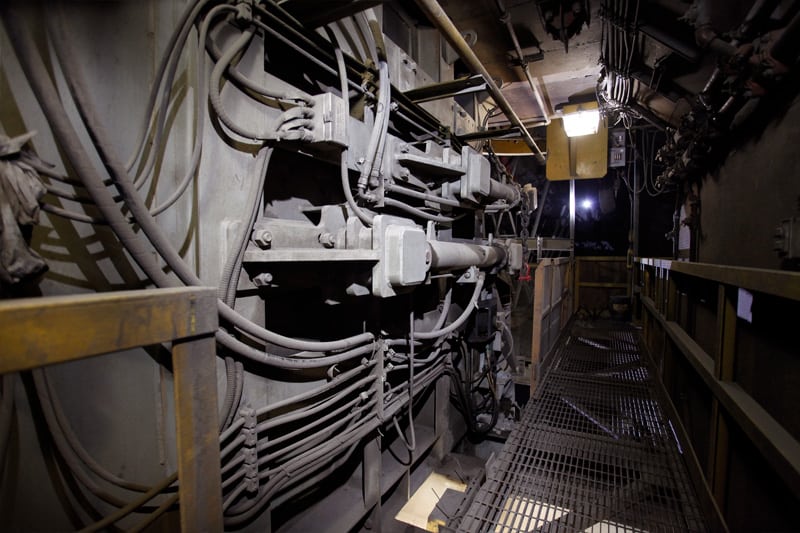

Rail Haulage Solutions

VMT proudly represents industry leader Clayton Equipment in North America – offering clients over 80 years of proven systems…

Wireless Control & Camera Systems

Variant Mining Technologies (VMT) strategically works with industry professionals to provide the latest in technologies for control systems…

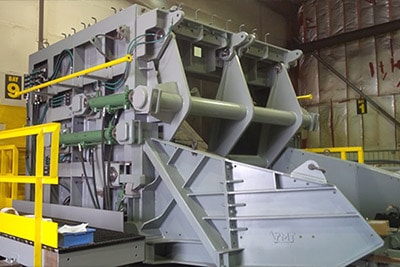

Descender Systems

Variant Mining Technologies (VMT) welcomes Descender Systems to our newest lineup of technologies and product lines…

Project Gallery

OUR PARTNERS

Ionic

OUR Customers

Dumas

Cementation

Hatch

Jacobs

KGHM

Agnico Eagle

Rio Tinto

nyrstar

NAP

Goldcorp

Kirkland Lake

Integrated Nickle

Newmont

Alamos Gold Inc

Vale

newgold

DMC

SCR Mining

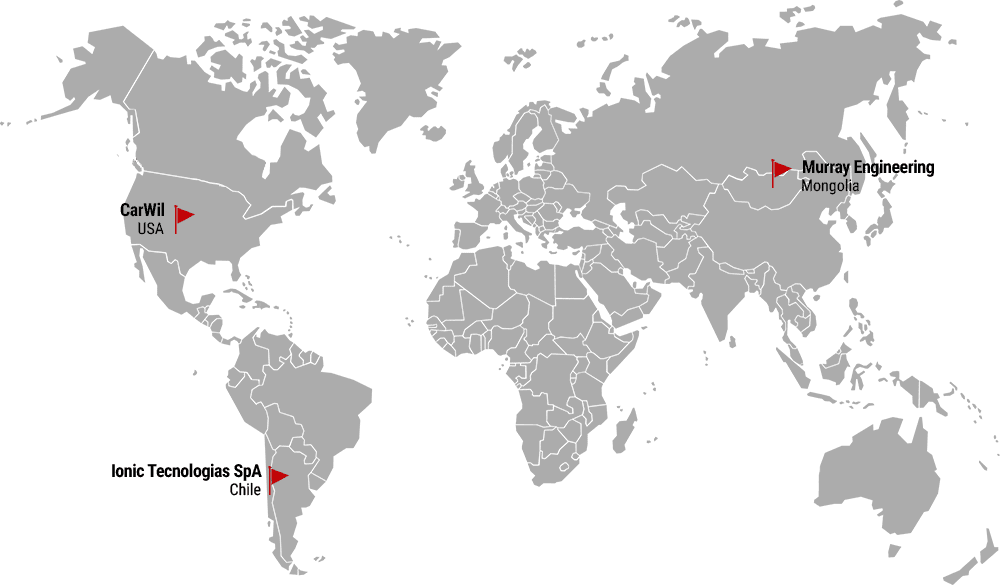

OUR DEALER NETWORK

Media Centre

Onaping Depth’s innovative lithium battery electric & semi-autonomous rail system

Clayton Equipment Ltd based in Burton-on-Trent, UK has sold and delivered five (with an option for a sixth) CB12.5 state of...

First-of-its-kind ore handling solution puts safety first

Mining companies are digging deeper than ever to maximize output, what starts as an open-pit mine often extends...

How this Sudbury man is honouring his friend by running

In the last few days of Steve Matusch's life, he had a conversation with his friend Andre Dumais about the importance of...

Contact Us

95 Mumford Dr, Lively, Ontario, P3Y 1L1