Vale and IONIC Engineering have designed a material handling system capable of packaging the concentrate into bulk bags at a rate of 24 to 32 tonnes per hour by integrating a Flexicon automated bulk bag filling system.

Vale and IONIC Engineering have designed a material handling system capable of packaging the concentrate into bulk bags at a rate of 24 to 32 tonnes per hour by integrating a Flexicon automated bulk bag filling system.

To handle the volume, Francois Nzotungwanimana, Operations Manager at Ionic Engineering and Project Engineer on the bulk bagging project, specified the dual bulk bag fillers, roller conveyors and a central pallet dispenser comprising the Flexicon system.

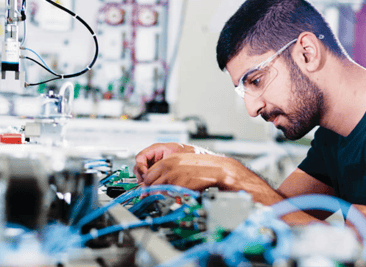

In addition, Ionic designed the electrical and control systems, sourced labelling machines and other equipment, designed safety systems and performed the systems integration including programming, electrical and safety. The Ionic Engineering team also performed additional mechanical design and safety engineering.